HIP Application

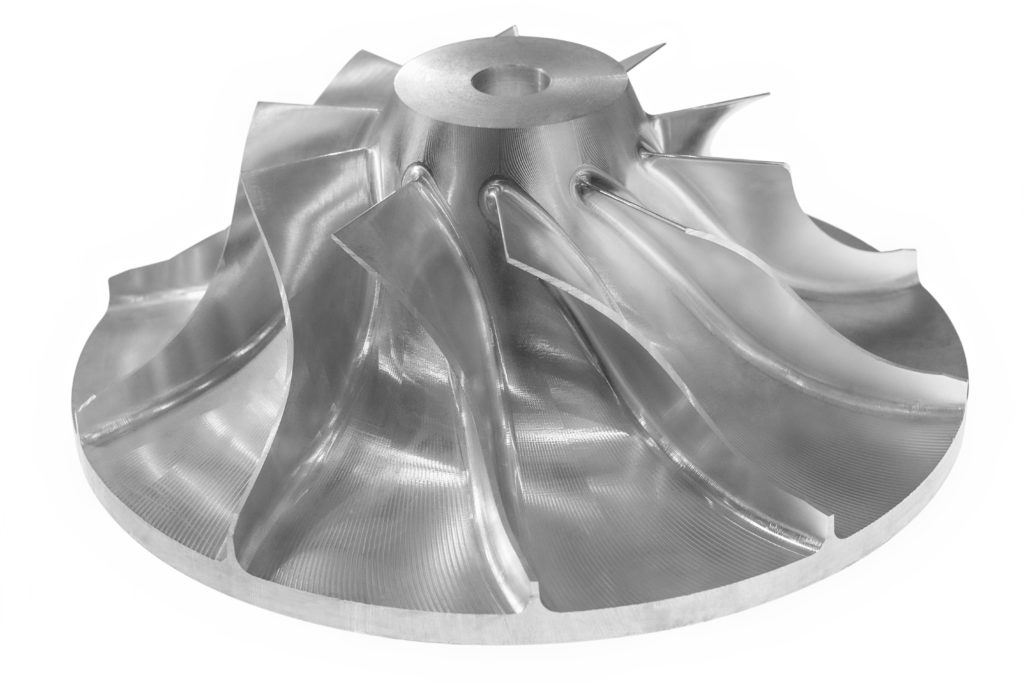

HIP systems are used in many of today's leading industries, such as aerospace, biomedical, industrial, automotive, electronics, defense and power generation.

HIP systems can be used with a wide variety of materials such as: Ceramics, Aluminum, magnesium, copper alloys, Nickel/Cobalt superalloys, Tungsten Carbide Titanium – cast and powders and Steel casting, Magnetic materials, and Plasma spray coatings

HIP Services

Actively expanding HIP systems

Contact us to inquire about our new units coming!

- Fast turnaround

- Precise Computer controlled with hard disk data logging

- Low cost

- Quality Assurance

- Numerous Industry Applications

- South-Central USA location

- Large hub of Federal Express shipping 15 minutes away

- Highly trained and experienced technicians and engineers

HIP Process

Hot isostatic pressing (HIP) is a process using high pressure and temperature over a set time to improve material properties. Precisely computer controlled to specific parameters yield the desired improved properties. A furnace is inside a pressure vessel is pressurized with argon. The uniform pressure and elevated temperature allows for desification and eliminating any product defects while at the same time improving the mechanical properties.

Isostatic Toll Services is committed to the providing our customers with the highest quality in the industry.

Our company currently has quality systems certified to ISO 9001/EN9100, AS9100 (Aerospace), and NADCAP AC7102\6:HIP.

About ITS

ITS is a growing toll HIP company located in Olive Branch, Mississippi. Our central location combined with low costs make us a first choice for companies that have small to medium size toll HIP requirements.

About ITS Bilbao

ITS Bilbao is a collaborative effort to break into the European market to provide quality Toll HIP services at a competitive price. With a brand new AIP52 unit and NADCAP/AS9100 certified, let ITS Bilbao manage all your production hipping needs.

Ready to find out more?

We are available to discuss your hot isostatic pressing needs. Work with experienced technicians who can assist with optimizing your run parameters based on product requirements.

Know what you want?

Send us the information about your parts and cycle parameters and we will get back to you with the industry's best price!